JEL-SET® 2.0: Precision Wax, Redefined

Westech pattern waxes have been the standard for reliability and quality for over 20 years. Pattern wax is the foundation of the investment casting process, and quality, consistent wax is crucial for investment casters to make a great casting.

Westech’s full line of pattern waxes is manufactured in the USA using our ISO-certified processes, developed and tested by our in-house laboratory, and distributed globally.

Our full line of pattern waxes for investment casting includes:

-

Filled Waxes

-

Non-Filled Wax (our innovative JEL-SET® Wax)

-

Soluble Waxes

-

Utility Waxes

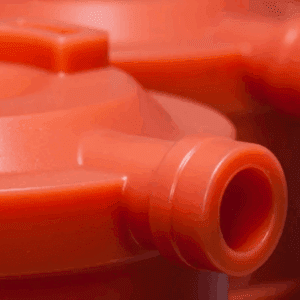

Our newest remarkable innovation in pattern wax is our non-filled JEL-SET® line.

JEL-SET® 2.0: Precision Wax, Redefined

JEL-SET® 2.0 is a next-generation wax engineered for superior performance in precision casting. Designed with consistency, efficiency, and cost savings in mind, it helps foundries achieve higher yields, fewer defects, and greater profitability.

Key Features & Benefits

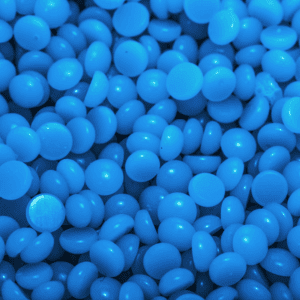

- Optimized Medium-Blue Color

Enhances visibility during inspection, making imperfections easier to spot, speeding up quality checks, and improving overall control. - Superior Cavitation Resistance

Outperforms traditional non-filled and even filled waxes (up to 40% filler), delivering cleaner patterns and greater reliability. - Predictable Dimensional Accuracy

With cavitation eliminated as a factor, customers can focus on achieving precise, linear dimensions every time. - Wide Temperature Stability (130°F–160°F)

Maintains consistent performance across a broad injection range, reducing variability and minimizing costly defects. - Enhanced Shell Crack Resistance

Lowers the risk of shell failure during dewaxing, resulting in higher yields and more dependable production runs. - Efficient Shell Coat Removal

Streamlines post-processing, cutting time, labor, and overall operating costs. - Proven Across Dewaxing Methods

Tested and validated in both flash fire and autoclave processes, ensuring consistent, dependable results. - Lower Specific Gravity

Delivers more usable product per batch, driving down material costs while boosting throughput. - Higher Reclaim Efficiency

Generates up to 25–50% more reclaim return per truckload — translating into thousands of dollars in annual savings.

Additional information

| Unit | BAG |

|---|---|

| Product Name | JEL-SET 2.0 |

| Weight | 50 LBS |

| Source/Vendor | Westech Wax |

| Data Sheet | https://westechdirect.com/jel-set-pattern-wax-product-data-sheet/ |

| Shipping Options | Will-call; Your Own Prepaid-Shipping; Contact Me to Coordinate |